Pipe fittings are an essential part of any piping system, connecting different pipes together and facilitating changes in direction. While threaded pipe fittings are common, non threaded fittings also offer benefits for certain applications.

Non threaded pipe fittings offer various benefits over traditional threaded fittings, including permanence, adjustability, leak resistance and lower friction loss. They connect pipes using methods like welding, flaring, grooving, pressing and clamping.

What Are Non Threaded Pipe Fittings?

Non threaded pipe fittings are fittings that connect pipes together without the use of tapered threads. They instead use methods like welding, pressing, crimping or clamping to form a joint between pipes.

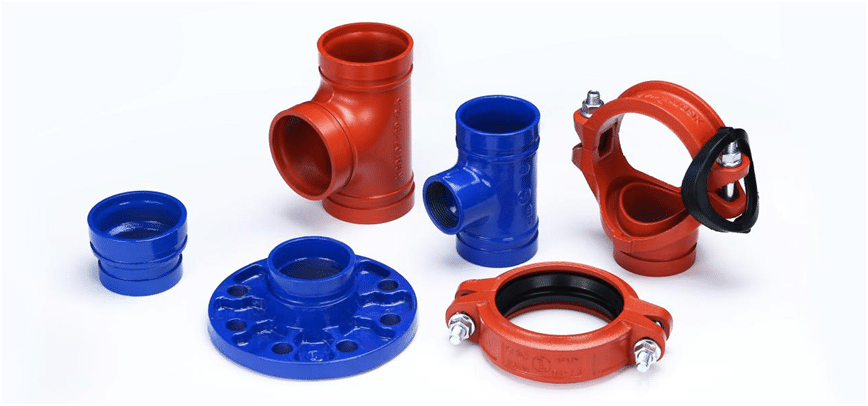

Common types of non threaded pipe fittings include:

- Sockolets – Pipe ends are flared out and inserted into a fitting socket, then compressed with a swage tool.

- Grooved fittings – Pipes have grooves cut into their ends that mate with a gasket-sealed fitting.

- Press fittings – Tubing is inserted into a fitting and compressed using a tool to create a permanent seal.

- Welded fittings – Pipe ends are heated and fused together with the fitting, creating a metallurgical bond.

- Flanged fittings – Pipes have flanges bolted directly to the fitting’s mating flange.

- Clamp fittings – Connect pipes using metal bands that are compressed to create a seal.

Non threaded pipe fittings are often made of:

- Galvanized steel – Durable and corrosion resistant, commonly used for water distribution and buried applications.

- Black iron – Lower cost option but requires painting or coating for corrosion protection.

- Stainless steel – Highly resistant to corrosion and chemicals, suitable for industrial and commercial use.

- Copper – Excellent conductivity for heating/cooling systems, but higher initial cost.

Benefits Of Non Threaded Pipe Fittings

- Permanent seal – Methods like welding and pressing create a leak-proof joint that lasts the life of the system.

- Tighter turn radius – Offer smaller bend radii than threaded fittings, important for compact installations.

- Less leakage – Threads in traditional fittings can wear over time and leak, while non threaded fittings maintain an optimal seal.

- Low friction loss – Geometry of non threaded fittings yields lower friction loss and higher fluid flow efficiency.

- Simple assembly – Methods like grooved, press and clamp fittings are faster and easier to install than threaded joints.

- Adjustability – Some non threaded fittings allow for minor movement to adjust piping alignment.

Non threaded pipe fittings are common in applications such as:

- Commercial & industrial piping systems – Grooved steel fittings are widely used.

- Compressed air systems – Grooved and flare fittings reduce air leakage compared to threaded joints.

- Plumbing systems – Press fittings allow for easy installation of tubing and piping.

- Irrigation systems – Use of PVC and polyethylene non threaded galvanized pipe fittings cuts installation time.